Bus bars, power module cases, connector parts, etc.

We convert various past product development requirements, die design and manufacturing, process design, quality requirements, and issues, etc. to digital data, particularly for automobile related products. We then strive to understand the quality requirements of the customer, and our well-experienced Die Technology Division, Manufacturing Division, and Quality Assurance Division work together from the stage of product development and drawings before mass-production, in order to propose achievable product shapes and processes.

We approach difficult problems from various perspectives via thorough hearings, creativity, and accumulated expertise, and aim to provide a primary response at meetings regarding whether manufacturing is possible as well as propose improvements.

We have experience with a wide range of proposals to meet diversifying customer needs, such as combinations of different materials in metal stamped inserts, differing plate thicknesses, and various types of plating.

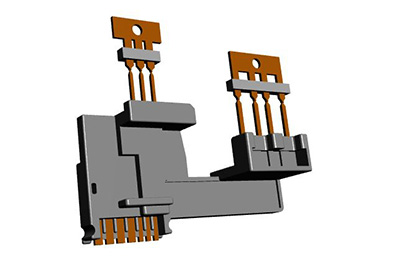

We receive many requests for integrating components in order to reduce the number of components used for assembly.

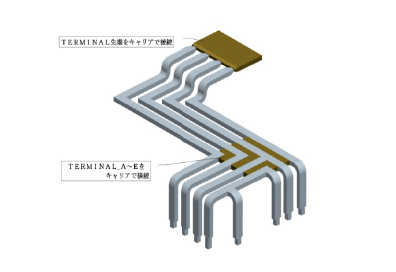

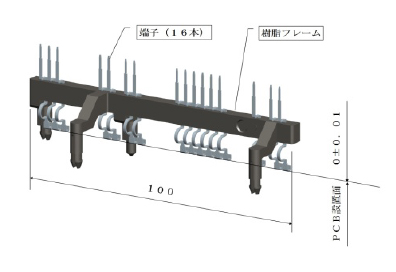

We have various ideas for metal stamped insert layouts and die insertion methods born from cooperation between our different divisions, such as connecting the tips and bases of terminals with a carrier and performing both division and resin formation at the end of the process.

We select outsert molding in order to reduce terminal deformation when the positional precision of delicate and complex metal stamped inserts cannot be maintained due to deformation caused by resin contraction after molding.

We have a wide range of other experience such as integrating multiple metal stamped inserts via resin molding and process overhaul to solve issues, such as the dramatic division of components.

We provide proposals that include the feasibility of maintenance after mass-production, drawing dimensions, and quality concerns such as functional assurance, upon understanding the assembly by the customer and product structure, and thereby minimize material loss.

Bus bars, power module cases, connector parts, etc.

PBT, PPS, PA(6・46・66), PPA, SPS, POM, PEI, PS, ABS, PC, etc.

Automobile, gas fittings, plumbing, electronic parts, aircraft, etc.

Electrodes, terminals, collars, nuts, etc.

Copper, brass, phosphor bronze, aluminum, stainless steel, iron, titanium, etc.