Product Information

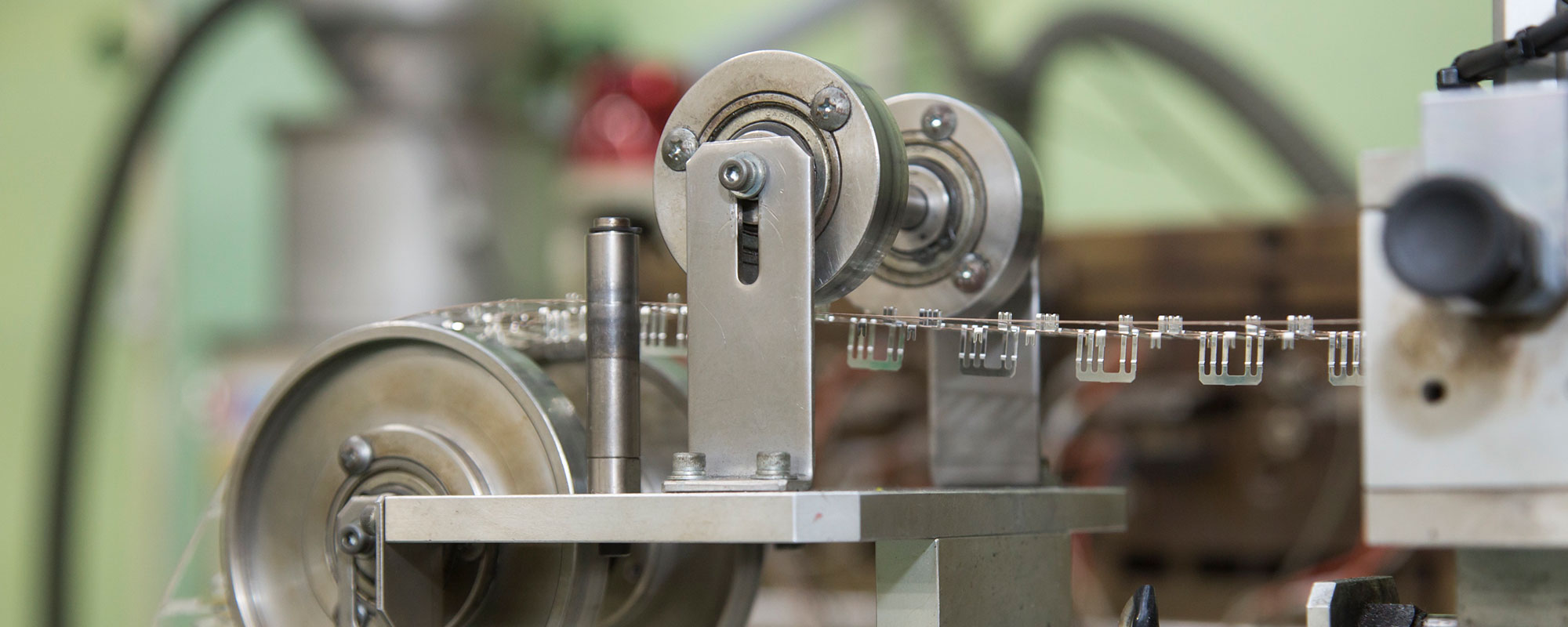

Automobile

Powertrain Systems (Engine)

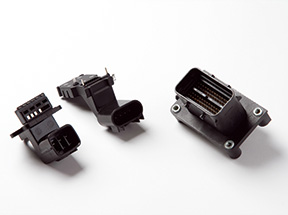

- Product name

- Body

- Application

- Air flow sensor

- Material

- PBT-GF30

- Precision

- From 0.1 mm

- Lot

- 7,000/month

- Molding machine

- Horizontal molding machine (180 t)

- Method

- Insert molding

- Point

- Roundness: 0.1 mm

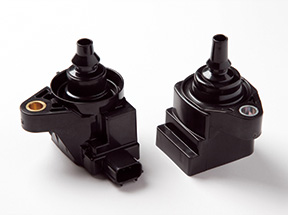

- Product name

- Cover

- Application

- Electronic throttle control

- Material

- PBT 733LD/C2680

- Precision

- From 0.1 mm

- Lot

- 5,000/month

- Molding machine

- Vertical molding machine (100 t)

- Method

- Stamping/premold molding/overmold molding

- Point

-

・Insert molding of terminals suitable for W/B (wire bonding)

・Dimensional precision in sensor part of ±5/100 mm

・Important to maintain terminal quality

- Product name

- Case

- Application

- Direct ignition system

- Material

- PBT 5010G30-TZ/C2680

- Precision

- From 0.1 mm

- Lot

- 350,000/month

- Molding machine

- Vertical molding machine (100 t)

- Method

- Stamping/insert molding

- Point

-

・Variation in void and thickness

・Molded products with thickness variation. A balance of die and mold technology is important.

- Product name

- Various gears

- Application

- Electronic throttle control

- Material

- PPA/PA46TW271

- Precision

- From 0.1 mm

- Lot

- 20,000/month

- Molding machine

- Horizontal molding machine (100 t)

- Method

- Insert molding/injection molding

- Point

-

・Gear grade

・Grade 6 of the AGMA American gear standard

- Product name

- Pipe

- Application

- Direct ignition system

- Material

- PPS 6565A7/C2600

- Precision

- From 0.1 mm

- Lot

- 300,000/month

- Molding machine

- 180t

- Method

- Injection molding

- Point

-

Electrical testing performed after injection molding

- Product name

- Rotating lever

- Application

- Electronic throttle control

- Material

- PA9T G1352A

- Precision

- From 0.1 mm

- Lot

- 50,000/month

- Molding machine

- 40t

- Method

- Automatic injection molding

- Point

-

・Shape inspected for all parts by camera after molding

・Automatic line ((1) Injection molding (2) Retrieval (3) Inspection (4) Packaging)

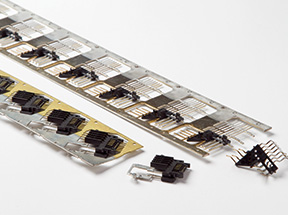

- Product name

- Primary molded product

- Application

- Electronic throttle control

- Material

- PBT 733LD/C2680

- Precision

- From 0.1 mm

- Lot

- 5,000/month

- Molding machine

- Vertical molding machine (60 t)

- Method

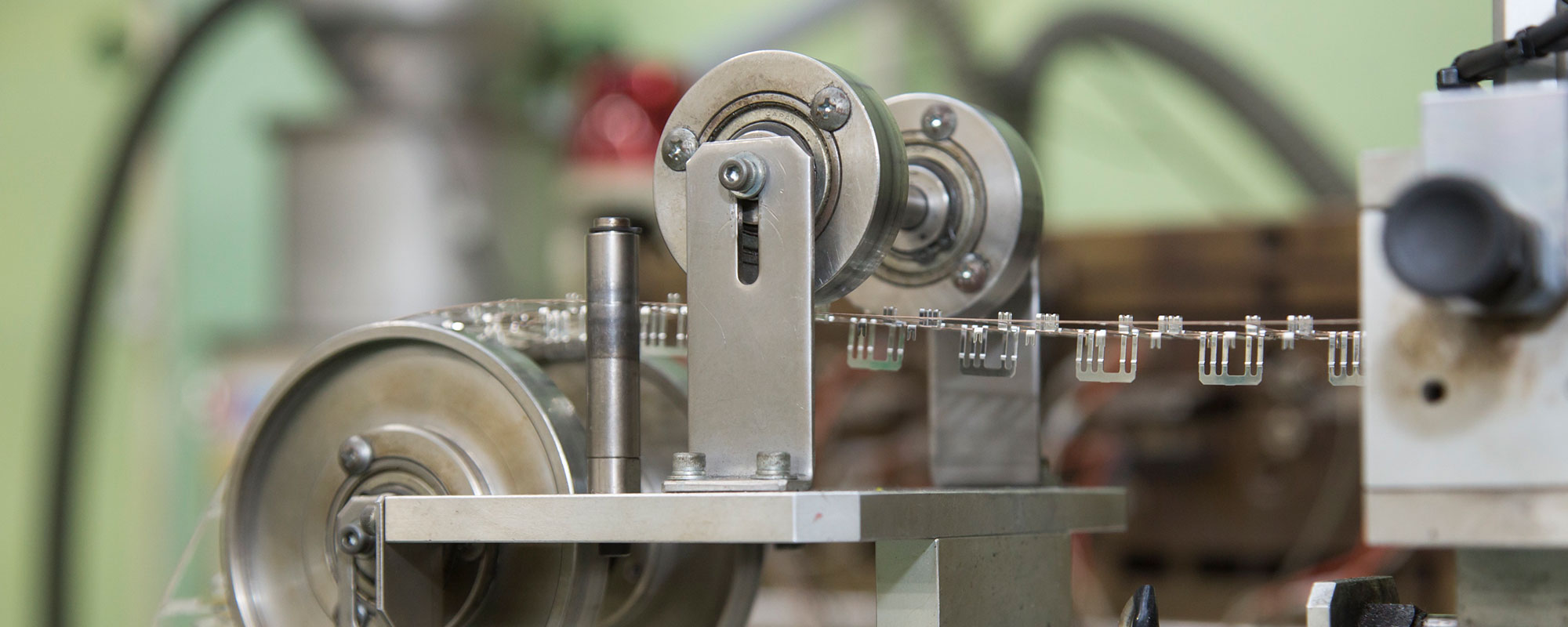

- Premold molding/hoop molding (inline molding)

- Point

-

・Type with cleaning device included in hoop molding (inline molding)

・Cleaning conditions equivalent to a plating company

- Product name

- Housing

- Application

- Engine cooling system

- Material

- PPS 1140A6

- Precision

- Minimum drawing deviation

- Lot

- 3,000/month

- Molding machine

- 140t

- Method

- Injection molding

- Point

-

-

Powertrain Systems (Electric)

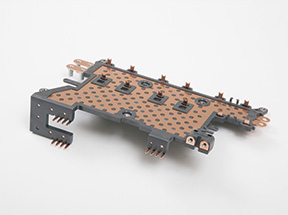

- Product name

- Bus bar

- Application

- Inverter for HEV

- Material

- PPS 6150T8

- Precision

- Minimum drawing deviation

- Lot

- 1,000/month

- Molding machine

- 220t

- Method

- Insert molding

- Point

- Utilizes fluid analysis to enable molding of thin shapes

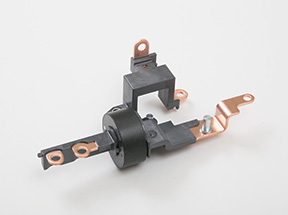

- Product name

- Core bus bar

- Application

- Inverter for HEV

- Material

- PPS 6150T8

- Precision

- Minimum drawing deviation

- Lot

- 5,000/month

- Molding machine

- 100t

- Method

- Insert molding

- Point

- Assembly with ferrite core attached after molding

- Product name

- Fuse holder

- Application

- Connector for HEV

- Material

- PPS 6150T8

- Precision

- Minimum drawing deviation

- Lot

- 1,000/month

- Molding machine

- 100t

- Method

- Insert molding

- Point

- Fluid analysis utilized during molding to ensure that the bus bar is not deformed due to the injection pressure

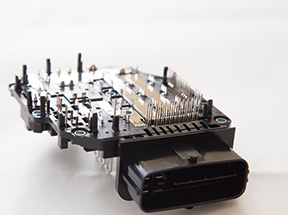

- Product name

- Body

- Application

- Inverter for hybrid system

- Material

- PPS A575W/C1100/C2680

- Precision

- From 0.1 mm

- Lot

- 2,000/month

- Molding machine

- Vertical molding machine (150 t)

- Method

- Stamping/insert molding (primary to tertiary processes)

- Point

- ・Optimal combination of molding processes from primary to tertiary

・Hoop molding (inline molding)

- Product name

- Sensor case Terminal block

- Application

- Current sensor for HEV

- Material

- PPS 6565A7/C1100

- Precision

- From 0.1 mm

- Lot

- 100/month

- Molding machine

- Vertical molding machine (100 t)

- Method

- Stamping/insert molding/adhesion

- Point

- ・Adhesion for insulation

・Complex mold structure supported with multidirectional sliding

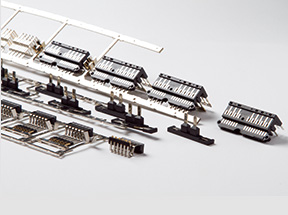

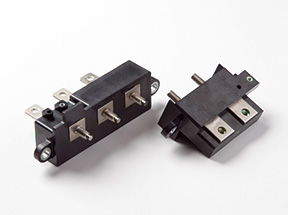

- Product name

- Various connectors

- Application

- Connector for HEV

- Material

- PBT 7390W

- Precision

- Minimum drawing deviation

- Lot

- 500/month

- Molding machine

- Vertical molding machine (100 t)

- Method

- Stamping/insert molding

- Point

- ・Premold (primary insert molding) type also available

・Metal processing also performed in molding die to increase cycle

Vehicle integrated control systems (chassis)

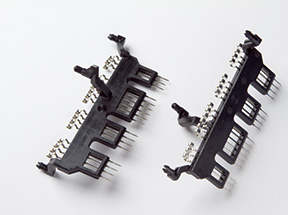

- Product name

- Bus bar integrated connector

- Application

- Electronic brake system

- Material

- PBT V4860HR

- Precision

- Minimum drawing deviation

- Lot

- 2,000/month

- Molding machine

- 150t

- Method

- Insert molding

- Point

- ・Premold products/terminal units/cutting components molded at once

・Achieves terminal alignment tolerance of ±0.05 mm

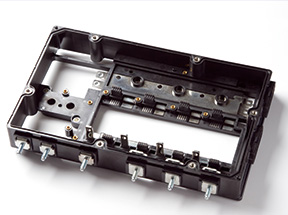

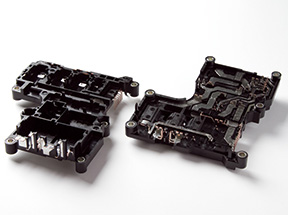

- Product name

- Bus bar module

- Application

- Electronic brake system

- Material

- PBT 5810G/C1020

- Precision

- From 0.1 mm

- Lot

- 5,000/month

- Molding machine

- Vertical molding machine (100 t)

- Method

- Stamping/insert molding

- Point

- ・Large number of insert components

・20 items or more, manually placed

・Adopted system for eliminating faulty products by checking the installation location of all insert components by camera

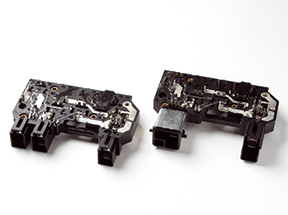

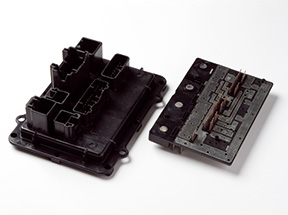

- Product name

- Bus bar module

- Application

- Electric power steering

- Material

- PBT 5810G30/C1020/C2600

- Precision

- Minimum drawing deviation

- Lot

- 50,000/month

- Molding machine

- Vertical molding machine (100 t)

- Method

- Stamping/insert molding/heat welding

- Point

- ・PCB terminals heat welded after molding

・Enables reduction in die costs and component costs

- Product name

- Lead frame

- Application

- Electric power steering

- Material

- PPS A310M/C2600

- Precision

- From 0.1 mm

- Lot

- 200/month

- Molding machine

- Horizontal molding machine (60 t)

- Method

- Stamping/injection molding/assembly

- Point

- Fix with heat welding after automatically aligning terminals and assembling the cover.

- Product name

- Lead frame

- Application

- Electric power steering

- Material

- PPS A310M/C2600

- Precision

- From 0.1 mm

- Lot

- -

- Molding machine

- Horizontal molding machine (60 t)

- Method

- Stamping/injection molding/assembly

- Point

- ・Fully automated line

(1) Stamping (2) Injection molding (3) Cover assembly (4) Fix with heat welding

Safety control systems

- Product name

- Primary molded product

- Application

- Steering roll connector

- Material

- PBT 2002/ED3002

- Precision

- Minimum drawing deviation

- Lot

- 50,000/month

- Molding machine

- Vertical molding machine (60 t)

- Method

- Hoop molding (inline molding)

- Point

- After line molding (inline molding) is complete, electrical inspection, image inspection, weighing and packaging are automated.

Other industries (other than automobile)

Marine vessels

- Product name

- Lower case

- Application

- Fuse case Fuse box

- Material

- PBT 5010GT-30/C1100

- Precision

- From 0.1 mm

- Lot

- 2,000/month

- Molding machine

- 150t

- Method

- Insert molding

- Point

- Flatness of primary molding: 0.2 mm

Injection molded products (without metal stamped inserts)

- Product name

- Band etc.

- Application

- Wiring fixing Cable ties etc.

- Material

- PA66 1300S

- Precision

- Minimum drawing deviation

- Lot

- 80,000/month

- Molding machine

- 180t

- Method

- Injection molding

- Point

- -